A temperature monitoring system for freezers ensures optimal storage conditions by continuously tracking and recording temperature levels. It helps prevent spoilage and maintains product quality.

Maintaining consistent temperatures in freezers is crucial for preserving perishable goods. A reliable temperature monitoring system can alert you to fluctuations that might compromise food safety. These systems often feature real-time alerts, data logging, and remote monitoring capabilities. By investing in a high-quality monitoring system, businesses can reduce waste, comply with health regulations, and ensure customer satisfaction.

The technology integrates easily with existing setups, making it a seamless addition to any operation. With accurate temperature control, freezers operate more efficiently, saving energy and reducing costs in the long run.

Importance Of Temperature Monitoring

Maintaining optimal conditions in freezers ensures food safety and prevents spoilage. Accurate temperature monitoring systems safeguard perishable goods, enhancing efficiency and reducing waste.

Protecting Perishables

Perishables need the right temperature to stay fresh. Temperature monitoring helps prevent spoilage. Fresh food tastes better and is safer to eat.

Spoiled food can make people sick. Monitoring systems alert you to temperature changes. Fix problems before food spoils.

Ensuring Compliance

Regulations require keeping food at certain temperatures. Temperature monitoring helps meet these rules. Avoid penalties and fines.

Compliance ensures food safety. Monitoring systems provide records of temperature data. Prove that you follow the rules.

Components Of A Monitoring System

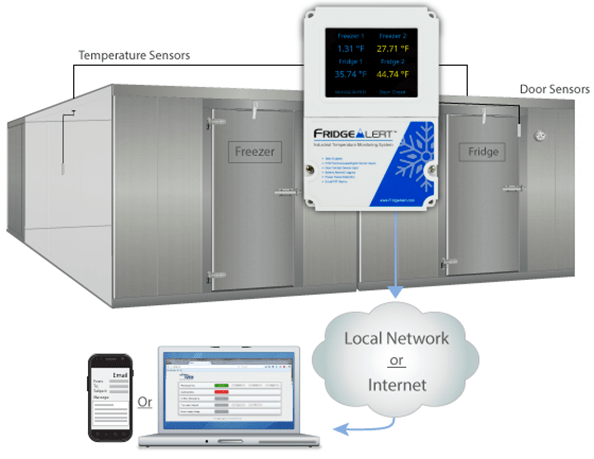

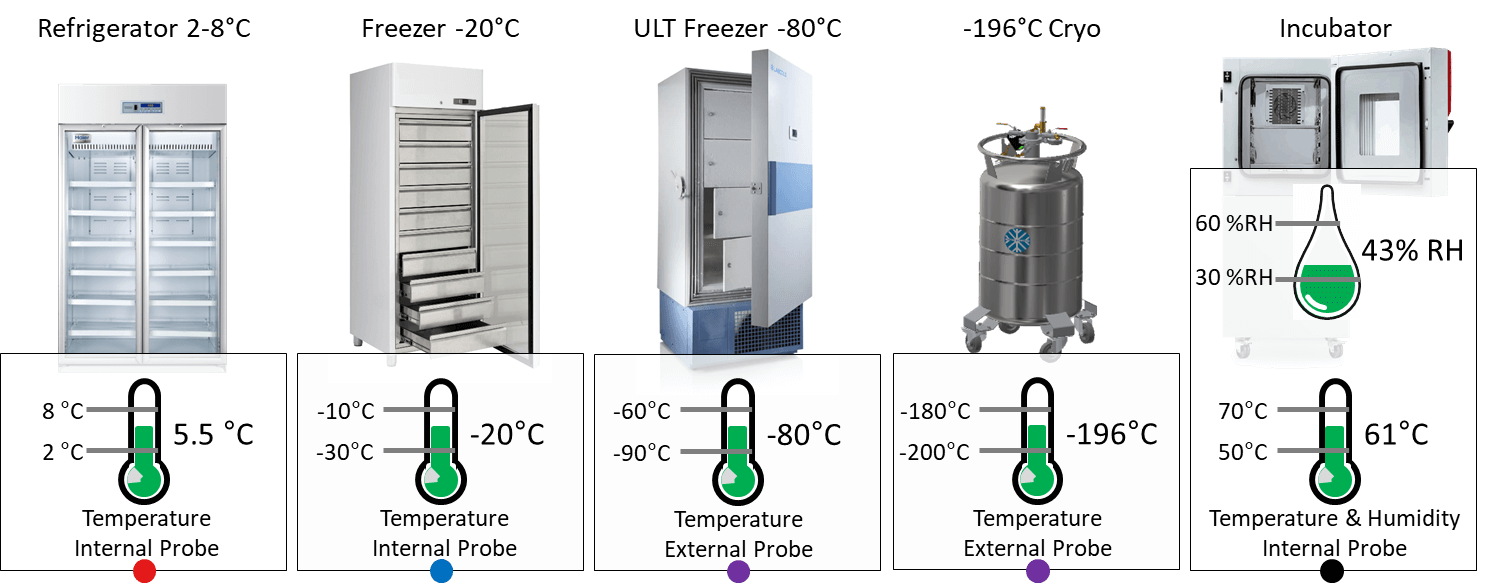

Sensors measure the temperature inside the freezer. They send data to the system. Sensors are accurate and reliable. They detect temperature changes quickly. This helps keep food safe. Different sensors can be used for different freezers. Some sensors work in very cold conditions. Others are better for warmer areas.

Data loggers record temperature readings. They store data over time. This helps track temperature trends. Data loggers can alert if temperatures go too high or low. They can be connected to computers or smartphones. This makes monitoring easy. Some data loggers have batteries. This means they keep working during power outages.

Types Of Temperature Sensors

Thermocouples are very common in freezers. They measure temperature using two different metals. The metals create a voltage when heated. This voltage shows the temperature. Thermocouples are cheap and durable. They work well in extreme temperatures.

RTDs are Resistance Temperature Detectors. They use the resistance of a metal to measure temperature. RTDs are more accurate than thermocouples. They are also more stable over time. RTDs are often made of platinum. This makes them more expensive.

Credit: controlbyweb.com

Real-time Monitoring

Monitor freezer temperatures in real-time to ensure optimal storage conditions. Prevent spoilage and maintain quality with constant temperature tracking.

Cloud Integration

Real-time monitoring uses cloud integration to track freezer temperatures. Data is sent to the cloud instantly. This allows for quick access from anywhere. Cloud storage ensures data is safe and accessible. Historical data can be reviewed for trends. Cloud integration makes monitoring simple and efficient.

Mobile Alerts

Mobile alerts notify users of temperature changes. Alerts can be sent via SMS or email. This ensures immediate action can be taken. Alerts can be customized for different thresholds. This feature helps prevent spoilage and loss.

Data Analysis And Reporting

Accurate data analysis and reporting enhance the efficiency of temperature monitoring systems for freezers. Real-time insights prevent potential spoilage and ensure optimal storage conditions.

Trend Analysis

Trend analysis helps spot temperature changes over time. This is crucial for freezer efficiency. Graphs show temperature patterns. Sudden changes can indicate problems. Regular monitoring keeps the freezer working well. Data helps improve freezer performance. Temperature trends help predict future issues. This saves money and time.

Automated Reports

Automated reports provide regular updates. These reports are easy to read. Important data is highlighted. Reports can be daily or weekly. Alerts are sent if temperatures vary. This ensures quick action is taken. Automated reports help maintain food safety. They are useful for audits and inspections.

Installation And Setup

Easily install and set up a temperature monitoring system for freezers to ensure optimal performance and food safety. Follow the straightforward instructions to get your system running efficiently in no time.

Hardware Placement

Place the temperature sensors inside the freezer. Ensure they are not blocked by food items. Attach the monitoring device outside the freezer. Make sure it is in an area with a stable power source. Use mounting brackets or adhesive strips to secure the device.

Software Configuration

Install the monitoring software on your computer or mobile device. Connect the software to the temperature sensors. Follow the on-screen instructions to complete the setup. Set alert thresholds for temperature changes. Enable notifications for real-time updates. Regularly check the software for updates to ensure optimal performance.

Maintenance And Calibration

Regular checks are vital for freezer performance. Check the sensors and alarms daily. Ensure the freezer stays at the correct temperature. Look for any signs of wear or damage. Clean the freezer to keep it running smoothly. Record all checks in a log book. This helps track any changes over time.

Calibration is crucial for accurate readings. Use a calibrated thermometer for reference. Place it inside the freezer for a few minutes. Compare the thermometer reading with the system reading. Adjust the system if there is a difference. Repeat the process until both readings match. Do this monthly to ensure accuracy.

Case Studies

Temperature monitoring is crucial in the pharmaceutical industry. Medicines and vaccines need a stable environment. Freezers store these sensitive items. If the temperature rises, medicines can spoil. Monitoring systems help maintain the correct temperature. Alerts notify staff about any issues. This ensures medicines stay effective and safe.

Food storage requires strict temperature control. Freezers keep food fresh and safe. Temperature monitoring systems detect any changes. If the freezer malfunctions, the system sends an alert. Staff can quickly fix the problem. This helps prevent food spoilage. It ensures the food remains safe for consumption.

Future Trends

Innovative temperature monitoring systems for freezers are revolutionizing food safety. These advanced systems ensure optimal temperature control, preventing spoilage and reducing energy consumption.

Ai Integration

AI can predict freezer temperature changes. It can alert users before problems happen. This keeps food safe and reduces waste. AI also learns from past data. This helps improve the system over time. Smart algorithms can adjust temperatures automatically. This saves energy and money.

Blockchain For Transparency

Blockchain records every temperature change. This makes data tamper-proof. Everyone can trust the data. It helps in tracking food safety. Consumers can see the history of their food. This builds trust between sellers and buyers. Blockchain also simplifies audits. It ensures compliance with safety standards.

Credit: www.tempcon.co.uk

Credit: www.elpro.com

Frequently Asked Questions

How Do I Monitor My Freezer Temperature?

Use a digital thermometer to monitor your freezer temperature. Place it inside and check regularly. Aim for 0°F (-18°C).

How Can You Check The Temperature Of Your Freezer?

Place a thermometer in the freezer. Wait 24 hours to get an accurate reading. Ideal temperature is 0°F (-18°C).

Where Do You Put A Temperature Sensor In A Freezer?

Place the temperature sensor in the center of the freezer. Ensure it is away from walls and direct airflow. This provides an accurate reading of the internal temperature.

How Often Should Fridge Freezer Temperatures Be Monitored?

Fridge freezer temperatures should be monitored daily. Regular checks ensure food safety and optimal appliance performance. Maintain consistent records for accuracy.

Conclusion

Implementing a temperature monitoring system for freezers ensures safety and efficiency. It helps prevent costly spoilage. With real-time alerts, you can maintain optimal conditions. Investing in this technology protects your inventory and enhances operational reliability. Stay ahead by integrating a robust monitoring solution in your freezer management strategy.